The DA19 user guide is designed to assist building owners and managers in better understanding the steps they need to take to use DA19 to specify their maintenance needs. Steps 1 to 6 outline how to use DA19 to develop a scheduled maintenance specification for your heating, ventilation, air conditioning and refrigeration (HVAC&R) assets, aligning with your maintenance duties and objectives and enabling you to define a building- or facility-specific HVAC&R maintenance package for competitive tendering. Step 7 highlights information on the further journey towards applying performance- or outcomes-based maintenance to your HVAC&R assets.

maintenance

objectives

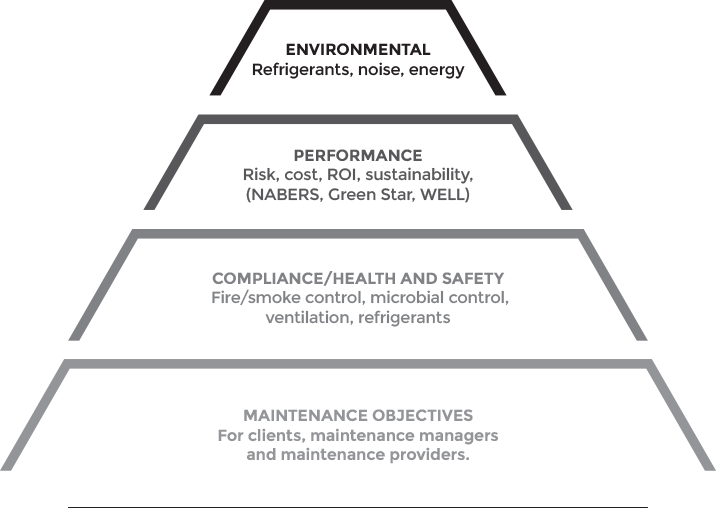

Define your overall maintenance objectives.

- Compliance requirements and WHS duties

- Short-term and long-term financial or organisational objectives

- Budget allocation to reflect objectives.

maintenance

objectives

What do you want

from maintenance?

Do you have compliance

requirements, WHS duties, short- or

long-term financial and organisational

objectives? Maintenance should be

planned, procured and delivered to

achieve the owner’s stated objectives.

These can include:

- Return on maintenance investment/asset protection and enhancement

- Legal compliance/health and safety

- Risk management/cost limitations

- Building sustainability/indoor environment quality

- Marketing/corporate image.

The budget allocated to funding maintenance should reflect the stated maintenance objectives.

Compliance with the law and associated statutory regulations applying to building or system maintenance is the minimum maintenance requirement that must be satisfied. Legal penalties apply for building owners and operators. Certification may be necessary to verify that maintenance obligations are being met. Specific legal requirements regarding the maintenance of HVAC&R systems can vary from state to state (and territory) in Australia.

Identify

and

understand

Identify and understand your HVAC&R assets.

- What and where are your HVAC&R assets – heating, cooling, refrigeration, fire safety?

- What assets have compliance, safety, energy or environmental impacts?

Identify your

HVAC&R assets

What, how many, and

where are your HVAC&R

assets?

Create an asset register for your

systems (heating, ventilation, air

conditioning, refrigeration, smoke

control) and

major components (fans, pumps,

boilers, chillers, filters, cooling

towers, package air conditioners.)

Identify every piece of HVAC&R plant and equipment on an asset register. Tag plant electronically to keep information up-to-date using bar codes, smart tags or scan codes.

Don’t forget the controls; maintenance of sensors, actuators, and DDC or BMCS controllers is essential.

Typical HVAC&R Assets

Heating – Reverse-cycle air conditioning, heating hot water, ducted heating

Ventilation – Supply, exhaust (bathrooms, kitchens, carparks, garbage)

Air conditioning – Central, distributed, rooftop, split systems, chilled beams

Refrigeration – Cool rooms, cold rooms, refrigerators, freezers, plant rooms

Fire safety – Fire dampers, smoke control systems, fire mode controls

Major components – Chillers, boilers, cooling towers, fans, pumps, control systems

Assign

a

criticality

Assign a criticality to each asset.

- Can your business or building operate successfully without this asset?

- What happens when it breaks down?

- Does it consume a lot of energy or water?

- Are there WHS risks?

Assign a

criticality

Assign a Criticality Risk Rating to each HVAC&R asset. Can your business or building live without this asset? What happens when it breaks down? Does it consume a lot of energy or water? Does it pose a potential safety risk? Does it affect your business?

This assessment is mostly about organisational and personal risks: financial income risks, WHS risks and public health risks.

Criticality risk rating = criticality/risk of HVAC&R services to the core business of the organisation.

Examples of enterprise critical HVAC&R services include:

- Cooling and air conditioning systems serving critical data centre and ICT processing functions

- Mechanical and HVAC plant and systems serving critical or acute care areas in hospitals

- Cooling systems in commercial building lift motor rooms or PABX/communications rooms.

Ventilation and air conditioning systems may also be designated as critical to continued building operations (ventilation or indoor air temperature), although longer downtimes can often be tolerated.

Refrigeration systems may be designated as critical, based on the nature or value of the service.

Select

a

maintenance

strategy

Select a maintenance strategy foreach asset (in light of steps 1 to 3).

- Assign a strategy for each asset

- Critical assets should be best practice

- Other assets will be good or best practice depending on objectives.

Select a maintenance strategy

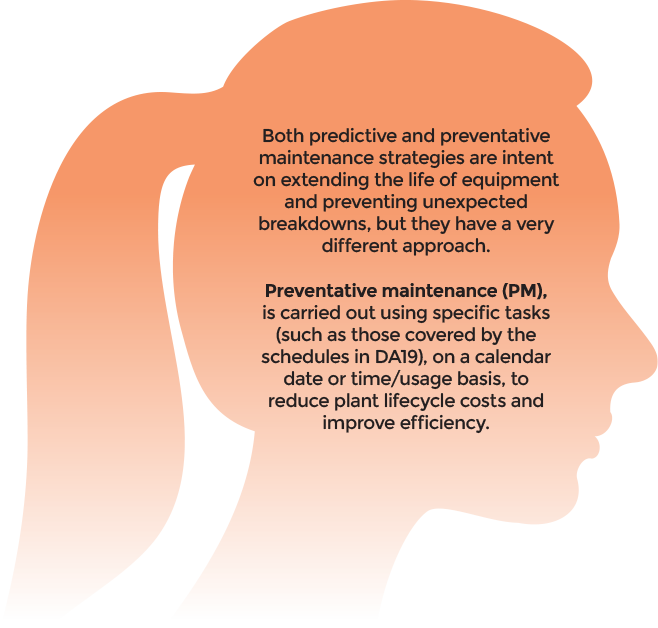

Select a maintenance strategy for each HVAC&R asset, in light of the decisions you have made in steps 1 to 3. Because of differing risk and criticality assessments, it is unlikely that a single maintenance strategy will be applicable to all of the HVAC&R assets within your building. DA19 allows for three levels of scheduled maintenance; best practice Level A, good practice Level B or compliance Level C maintenance. All assets should receive a minimum of compliance Level C maintenance. Critical assets should receive best practice Level A. Other assets should receive good practice Level B or best practice Level A, depending on the objectives.

MAINTENANCE

MINDSETS

Proactive or Reactive?

MAINTENANCE

MINDSETS

Reactive or Proactive?

EXAMPLE – ASSIGNING MAINTENANCE STRATEGY TO HVAC&R SYSTEMS

| HVAC&R asset | Criticality | Reason | Maintenance strategy |

| Refrigerant chiller | Critical | Serves critical process Contains > practical limit flammable refrigerant Energy use > X kJ |

PdM |

| Kitchen exhaust | High risk | Potential fire risk Potential odour complaints |

PM – Level A |

| Air conditioning system | Critical | Outdoor air ventilation (for occupation) Energy use > Y kJ |

PM – Level A PdM |

| Toilet exhaust | Standard | Non-critical, natural alternative | PM – Level B |

| Split air conditioner | Standard | Non-critical, natural alternative | PM – Level B |

LAYOUT OF A TYPICAL DA19 MAINTENANCE SCHEDULE

| Action | Frequency (m) | Explanation | ||

| Maintenance level | ||||

| A | B | C | ||

DA19 scheduled maintenance tender documentation needs to define the maintenance level to be applied to each system or item of plant – best practice Level A, good practice Level B, or minimum compliance practice Level C. From this, DA19 provides detailed maintenance schedules with instructions and specified maintenance task frequencies.

GOOD PRACTICE VERSUS BEST PRACTICE MAINTENANCE

Compliance

Level

Maintenance

|

|

| Good

Practice Maintenance

|

|

| Best

Practice Maintenance

|

|

tender

package

Put a tender package together.

- Document

your maintenance

requirement using DA19 - Identify

each system, the objective,

and the strategy.

tender

package

Document your maintenance requirement using DA19.

- (bullet) Put a tender package together, listing the system or HVAC&R asset, with the objective and the selected scheduled maintenance level

- Talk to service providers in terms of systems; they will break scheduled maintenance tasking down into component level in accordance with DA19 procedures.

EXAMPLE

Documenting DA19 scheduled

maintenance requirements for

HVAC&R

systems

| HVAC&R asset | Objective | Criticality rating | DA19 maintenance level |

| Air cooled chiller | Asset protection, risk and compliance, energy and NABERS | Reliability – serves

critical process Health and safety – refrigerant compliance Efficiency – high energy use > X kJ |

Level A and C |

| Kitchen exhaust | Risk and compliance | Health and safety –

potential fire risk Health and safety – potential odour complaints |

Level A and C |

| Air conditioning system | Asset protection and compliance |

Reliability – serves

operational staff area

Health – outdoor air

ventilation

Safety – fire dampers and smoke controls Efficiency – medium energy use > Y kJ |

Level B and C |

| Toilet exhaust | Standard | Non-critical, natural alternative, no compliance | Level B |

|

Split-system air conditioner |

Standard | Non-critical, natural alternative, no compliance | Level B |

tender

quote

Seek a tender quote.

- Hand the tender package over to

HVAC&R maintenance companies

for a competitive tender quote.

tender

quote

Issue maintenance tender package for a competitive tender – you now have enough information to hand over to a HVAC&R maintenance company for a competitive tender or quote on your specific maintenance specification.

In any maintenance program, detailed maintenance instructions for all HVAC&R assets need to be compiled. DA19 provides detailed maintenance schedules with instructions and specified maintenance frequencies (Level A, B or C). The scheduled maintenance program for HVAC&R assets is developed from an amalgamation of all the individual DA19 maintenance schedules and task instructions to create a facility-wide systems approach to maintenance delivery.

Maintenance Budget

Lowest price is not the best criteria on which to assess competitive maintenance tenders.

The best way for owners and managers to optimise maintenance outcomes and expenditure is to enter into a long-term partnership with a maintenance service company and agree on a best-practice approach to maintenance – including agreed maintenance performance standards.

THE MAINTENANCE PARTNERSHIP

|

Role of FM in maintenance The

facility manager

acts on behalf of

the owner or demand

organisation to

ensure Managers need to respond to complaints quickly and efficiently and drive the maintenance process. They may also:

Successful maintenance management relies on the ongoing commitment of managers to maintenance planning, maintenance funding and user education.

|

Selecting a maintenance provider The selection of the maintenance service provider is the key to satisfactory maintenance, which will result in reliable plant performance, good plant life and reasonable expenditure. Lowest tender price is the least appropriate way to select a service provider. Value for money should be the determining factor. The ideal situation is where the demand organisation (client) and maintenance service provider establish a partnering relationship, recognising that the service provider needs to make a profit and the client needs to contain the costs. A potential service provider should have the following attributes:

|

performance-based

maintenance

Secure a performance-based maintenance arrangement.

- Now you know what you want from maintenance, you have the opportunity to enter into a performance-based maintenance arrangement with your maintenance provider.

performance-based

maintenance

Moving to performance-based maintenance

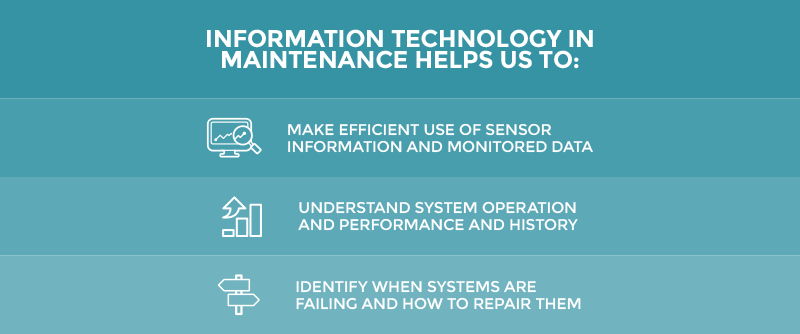

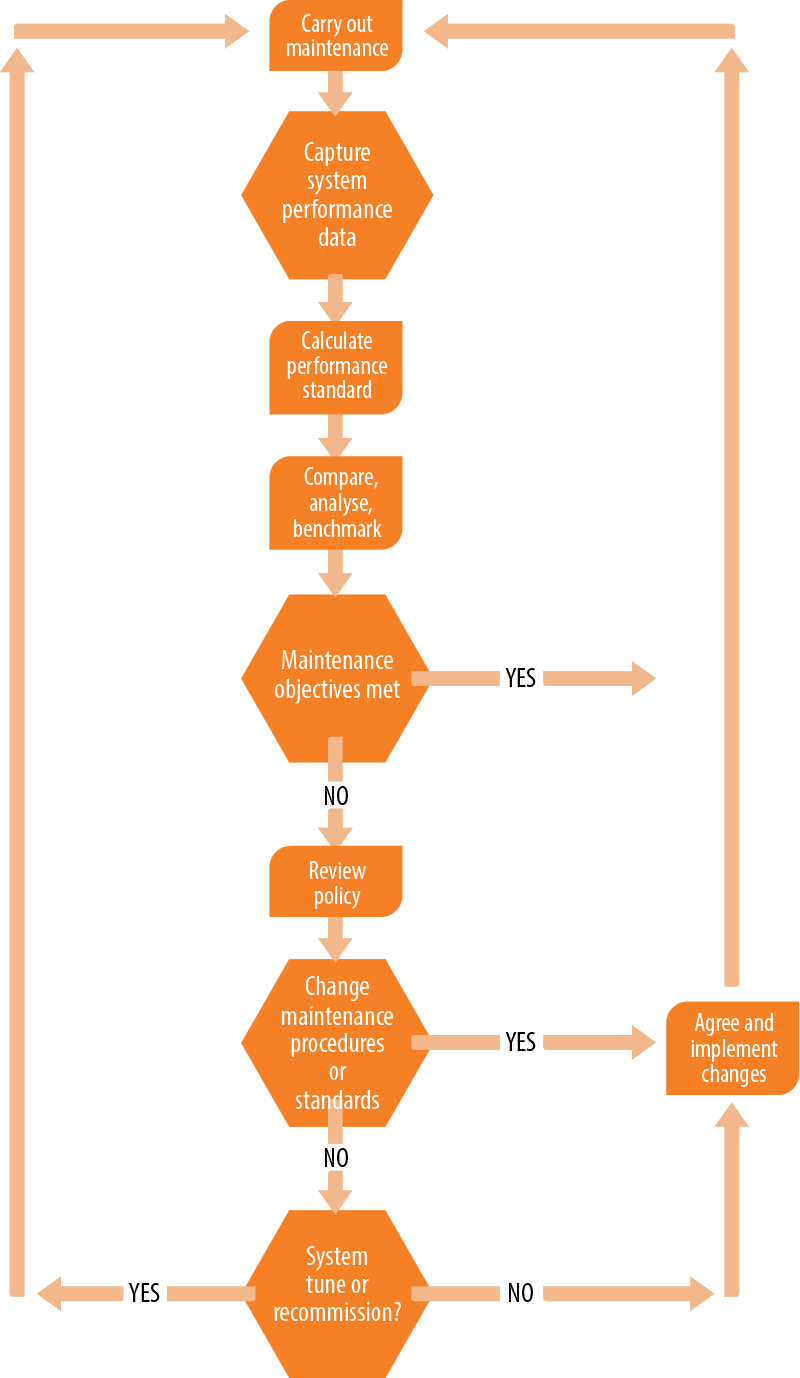

A performance-based maintenance regime applies an optimum mix of different maintenance approaches (preventative and predictive), based on risk, costs and consequences. Establishing the appropriate mix and focusing on continuous improvement are equally important in a performance-based maintenance strategy.

A performance-based maintenance delivery model requires a longer-term commitment from both parties as significant effort is required to get the processes matched to the outcomes.

Prescriptive or performance maintenance mindset – task versus outcome focus

It is best practice for owners to recognise the partnership and teamwork that must exist with HVAC&R maintainers (and possibly other specialist trades such as BMCS specialists) in order for the objectives of the maintenance program to be met. This requires clear communication of the objectives, how they will be measured and the frequency of measurement. Ideally, a series of lead and lag indicators will be used to guide the performance of maintenance, so that there is a high probability of the objectives being achieved.

See the suggested examples of potential lead and lag indicator measures that owners could use to target the outcomes that meet their objectives for the maintenance performance standards of HVAC&R asset maintenance in a commercial building. Please note: measures and frequencies are suggestions only.

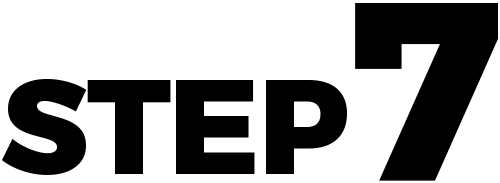

Maintenance, performance and digitisation

Another issue to consider is how digital information technology can be leveraged to generate improved maintenance outcomes in a performance-based approach. Applying digital solutions to maintenance planning, delivery and assessment is called smart maintenance in DA19.

Smart maintenance is a digital transformation strategy based on new technologies that capture data, automate tasks and free up human resources. Not all maintenance functions can be digitised, so smart maintenance uses digital intelligence to reduce the number of technician site visits while delivering superior service.

| OUTCOME | COMPLIANCE | HEALTH AND SAFETY | ||

| LEAD INDICATOR MEASURE | Monthly – compliance tasks completed to schedule | Monthly

– owners safety

inductions up-to-date

for all personnel;

safe

work management

plan

up-to-date

Tool box talks held to schedule |

||

| LAG INDICATOR MEASURE | Annual – compliance statement | Monthly – lost time injury frequency and lost time register |

| COMFORT CONDITIONS | ENERGY PERFORMANCE | WATER PERFORMANCE | ||

|

Daily – zone DB temp within 21.5°C to 23.5°C during occupied hours |

Daily

–

energy

monitoring Daily

–

energy

optimisation |

Daily

–

water

monitoring |

||

|

Monthly

–

customer |

Monthly – base building rolling annual energy/m2 < 375 MJ/m2 Annual – base building NABERS energy rating > 4 stars |

Monthly – base building rolling annual water/m2 < 600 L/m2 Annual – base building NABERS water rating > 3.5 stars |

| INDOOR ENVIRONMENT QUALITY | INDOOR ENVIRONMENT QUALITY | OUTDOOR ENVIRONMENT | ||

|

Daily

–

CO2

in the 100% < 1000ppm 90% < 800ppm |

Monthly

–

filters

cleaned |

Quarterly – plant noise measured |

||

|

Quarterly – ventilation system settings checked to schedule |

Quarterly

–

particulates in

air monitoring

PM2.5

< 25

µg/m3 |

Annual

–

compliance |

| RELIABILITY | SYSTEM DOCUMENTATION | MAINTENANCE PERFORMANCE | ||

|

Monthly

–

preventative |

Monthly – change register; records any changes to the physical system or operating parameters |

Monthly – performance meetings are held with maintenance team; performance objectives achieved |

||

|

Monthly – system reliability KPI, availability hours |

Monthly – changes are reflected in asset register, system drawings, functional specifications, maintenance documents |

Annual Review – with maintenance team; performance objectives reviewed |

| OUTCOME |

| LEAD INDICATOR MEASURE |

| LAG INDICATOR MEASURE |

| COMPLIANCE |

| Monthly – compliance tasks completed to schedule |

| Annual – compliance statement |

| HEALTH AND SAFETY |

| Monthly – owners safety inductions up to date for all personnel Safe work management plan up to date Tool box talks held to schedule |

| Monthly – lost time injury frequency and lost time register |

| COMFORT CONDITIONS |

| Daily – Zone DB temp within 21.5°C to 23.5°C during occupied hours |

| Monthly – customer complaint frequency |

| ENERGY PERFORMANCE |

|

Daily – energy monitoring < benchmark Daily – energy optimisation routines enabled |

|

Monthly – base building rolling annual energy/m2 < 375 MJ/m2 Annual – base building NABERS energy rating > 4 stars |

| WATER PERFORMANCE |

| Daily – water monitoring < benchmark |

|

Monthly – base building rolling annual water/m2 < 600 L/m2 Annual – base building NABERS water rating > 3.5 stars |

| INDOOR ENVIRONMENT QUALITY |

|

Daily

–

CO2

in the 100% < 1000ppm 90% < 800ppm |

| Quarterly – ventilation system settings checked to schedule |

| INDOOR ENVIRONMENT QUALITY |

|

Monthly

–

Filters

cleaned |

|

Quarterly – particulates in air monitoring PM2.5 < 25 µg/m3 PM10 < 50 µg/m3 |

| OUTDOOR ENVIRONMENT |

| Quarterly – plant noise measured |

|

Annual

–

compliance |

| RELIABILITY |

|

Monthly

–

Preventative |

| Monthly – system reliability KPI, availability hours |

| SYSTEM DOCUMENTATION |

|

Monthly – change register; records any changes to the physical system or operating parameters |

|

Monthly – changes are reflected in asset register, system drawings, functional specifications, maintenance documents |

| MAINTENANCE PERFORMANCE |

| Monthly – performance meetings are held with maintenance team; performance objectives achieved |

|

Annual Review – with maintenance team; performance objectives reviewed |

performance-based

maintenance

A lot of maintenance procedure is about information – generating data, comparing and analysing information, recording results. Managing information flows lends itself well to digitisation, and advances in digital technologies are providing new opportunities for more advanced maintenance services and solutions.

Time analytics pulled from big data, relayed by wireless sensor networks, analysed by cloud-based algorithms and visualised on mobile computing devices, are changing maintenance, disrupting traditional practices and creating new value opportunities.

Smart maintenance can deliver customer value by providing a real-time view of their maintenance needs, so they can make informed decisions. Collected data is used effectively to improve plant and system efficiency and guarantee user satisfaction.

For smart maintenance, it is essential that every item of plant/equipment be identified on the asset register.

| Asset register to record plant data |

An HVAC&R asset register is a record of all assets associated with the building or facility HVAC&R systems; components of a system are sub-assets. HVAC&R plant is a sub-asset of the whole building asset list. Each asset and sub-asset is given a unique identifier on the register which then provides a structure for recording and retrieving maintenance information. Each item listed should be included in the HVAC&R maintenance program. |

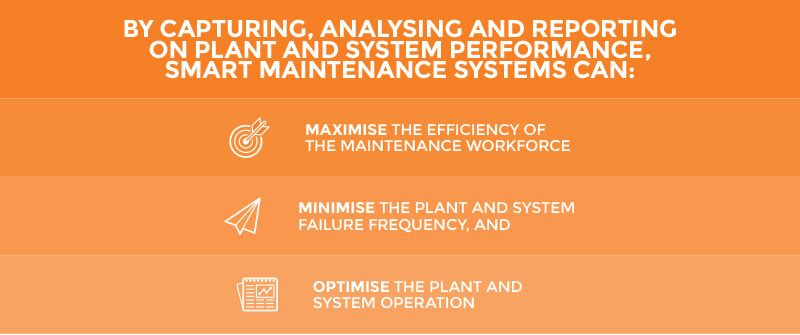

| Digitising asset information |

Asset lists should be provided in an electronic format to facilitate the construction of digital maintenance schedules and building logbooks, and to support the operation of maintenance management systems and field data capture and reporting devices. Plant can be electronically tagged with the asset register information and identified using bar codes, smart tags or similar. BIM data is leveraged into facilities management data. |

| Asset register to record plant data |

|

An HVAC&R asset register is a record of all assets associated with the building or facility HVAC&R systems; components of a system are sub-assets. HVAC&R plant is a sub-asset of the whole building asset list. Each asset and sub-asset is given a unique identifier on the register which then provides a structure for recording and retrieving maintenance information. Each item listed should be included in the HVAC&R maintenance program. |

| Digitising asset information |

|

Asset lists should be provided in an electronic format to facilitate the construction of digital maintenance schedules and building logbooks, and to support the operation of maintenance management systems and field data capture and reporting devices. Plant can be electronically tagged with the asset register information and identified using bar codes, smart tags or similar. BIM data is leveraged into facilities management data. |

Condition monitoring uses several advanced digital techniques to assess the condition and performance of components so that optimum equipment performance can be sustained.

When applying condition monitoring:

- Always obtain base readings early in the life of the equipment

- Undertake monitoring on a regular basis and plot trends

- Always

attempt to get a high signal to

noise ratio for the

measured variable - Always measure at fixed reference points

- Remove all other variables.

Once the results have been reviewed, maintenance actions are initiated by the trends highlighted.

In data-driven analytics, the physical condition, performance, or efficiency of a system is evaluated by monitoring selected digital input/output data and comparing the actual data received against a defined baseline. Any variance in the two datasets is used to identify the appropriate maintenance intervention. Using a combination of digital monitoring and analytical software algorithms, this process can be automated to a large extent, providing both continuous monitoring and alarm, as well as automated fault detection and diagnosis.

|

Software as a Service (SaaS) is a software licencing model where the software platform is hosted in a remote centralised location (cloud servers). The SaaS model is becoming more prevalent in HVAC&R for energy management and fault detection and diagnostics. |

|

|

|

Digitised asset registers and digital platforms (BIM, BMCS and CMMS) are going to play a huge part in the near future of data driven maintenance.

Protecting maintenance information and data

We all know about the threats of cybersecurity around data acquisition and storage. It is essential to have an Information Management Plan, with security management at its core. Security strategies should be part software or computational, and part user awareness with access control and threat protection.

Targeted

maintenance

Make maintenance work for you and make energy, water and refrigerants a focus for your maintenance provider. Monitor what you are using; manage your consumption; apply continuous improvement to your systems. Always review what you are doing. Are your maintenance objectives being met? Are you getting return on your investment?

REMEMBER that maintenance delivers on the triple bottom line – your people, your planet and your profit.

DA19 is used throughout the Australian property, facility management and HVAC&R maintenance industries as the authoritative guideline for HVAC&R maintenance. It is a document that can be used by an owner, operator or manager, as well as the service technician who does the technical work in the plant room. Further comprehensive information on all of these topics is provided in AIRAH’s DA19 HVAC&R Maintenance.

This DA19 user guide is endorsed by the Property Council of Australia (PCA), the Facility Management Association (FMA) and the Air Conditioning and Mechanical Contractors Association (AMCA).

Property owners – all property owners are interested in retaining and enhancing the value of their assets. This means investing in the maintenance of the building services and being specific about the objectives and expectations of that investment. Maintenance objectives have to reflect the asset owners’ objectives for health and safety compliance, asset performance and financial resources (both Operational and CapEx).

Facility managers – it is not sufficient for a facility manager to specify maintenance “in accordance with DA19”. DA19 is not a maintenance specification and a range of decisions must be made to define the scope and extent of the maintenance program required. Maintenance investment must reflect the risk to the business and the performance level required of the asset. Assets with high performance expectations require performance oriented outcomes-based maintenance approaches.